Protecting your equipment against shorts to earth will help keep the plant processes safer and keep damage from faults at a minimum. The best approach is to install fast acting ground fault relays as close to the individual loads as possible. Low level faults, quite often caused by deteriorating insulation in motor windings, are not nearly as dangerous or destructive as high level faults where one conductor contacts a grounded path with little resistance. Once there is even a minor leakage of current to earth, unwanted heating is bound to increase and with it more damage. Shutting down only the part of the process that is failing is the most sensible approach.

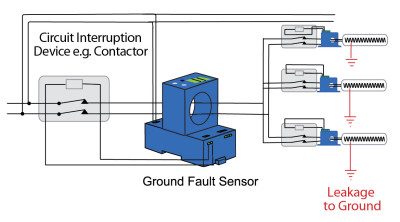

Use one ground fault relay to protect the circuit at or near the main disconnect (circuit breaker or contactor) and smaller relays downstream to protect each individual load.

The smaller relay will trip before the first, so only part of the process will be interrupted. The relay nearest the source power will remain ready if a larger fault or several small faults occur downstream.

When the distribution panel feeds several loads such as heat trace cable runs, multiple heating elements, or a number of motors, each circuit can be passing low magnitude current to earth (5 to 10 mA) without much damage to each individual load. However if there are ten loads, each leaking 10 mA, the “normal” ground fault current is now 100 mA. This is getting into the more dangerous level, even when the equipment operators are fairly well insulated from earth with gloves and boots.

A common practice is to add another ground fault relay at the main breaker and provide some delay to the output so that short periods of fault current will not shut down the entire process. This method improves the safety of the system and helps protect personnel who need to work on the equipment while it is energized. Some inductive loads like motors and transformers can cause a standard ground fault relay to trip when the load is first energized, so using a relay with some delay added will keep these occurrences from shutting down the system while keeping the equipment safe.

In the example to the right, several heating elements are protected by individual ground fault relays connected to separate contactors. If one element faults to earth, the relay will detect that condition and shut off just that part of the circuit, while the relay protecting the feeding circuit remains at the ready. If the insulation of each element begins to deteriorate and starts to pass small amounts of current to ground, the relay installed at the main panel will detect the sum of the leaking current and shut down the system after the delay. This will keep the feeding circuit from causing excess heat and the damage that heat will cause without protection.

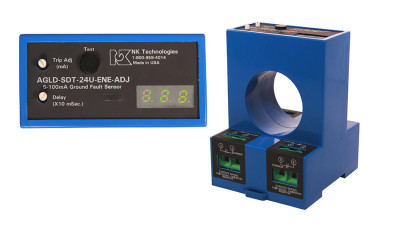

New AGLD Series Ground Fault Relay with Digital Display

New AGLD Series Ground Fault Relay with Digital Display

AGLD Series ground fault relays keep machinery and their operators safe from accidental shocks. The large, one piece solid-core design allows for installation over wires feeding heavy loads. The output relay will change state at any point between 5 mA and 100 mA, or 80 mA and 950 mA. The LED display will show the amount of fault current that will cause the output relay to change state. A delay can be set to allow down stream protection to activate before this relay, keeping the main circuit protection hot and the equipment energized while the smaller faults are cleared.