In North America, most people are familiar with ground fault circuit interrupters (GFCI) since they have been required by the National Electric Code since the early 1970’s. The first requirements to protect against hazardous electrical currents passing to ground were places where wet surfaces would meet bare feet. The chronological implementation of the requirements in North America were the following (according to Wikipedia):

Beginning with underwater swimming pool lights (1968) successive editions of the code have expanded the areas where GFCIs are required to include:  construction sites (1974), residential bathrooms and outdoor areas (1975), residential garages (1978), areas near hot tubs or spas (1981), hotel bathrooms (1984), kitchen counter receptacles (1987), crawl spaces and unfinished basements (1990), near wet bar sinks (1993), near laundry sinks (2005)[13] and in laundry rooms (2014).

construction sites (1974), residential bathrooms and outdoor areas (1975), residential garages (1978), areas near hot tubs or spas (1981), hotel bathrooms (1984), kitchen counter receptacles (1987), crawl spaces and unfinished basements (1990), near wet bar sinks (1993), near laundry sinks (2005)[13] and in laundry rooms (2014).

The primary purpose was to reduce the number of deaths caused by electrical shock. Once the design bugs were worked out with the devices, and they became quite reliable, the death toll was reduced dramatically. Any place where a human body might become the best path to ground is a candidate for ground fault circuit protection.

The GFCI receptacles and circuit breakers were a huge step forward. With the success in protecting people from shock, the interest in ground fault protection increased. A GFCI is designed to disconnect a circuit if current to earth exceeds 6 mA at 120 VAC in locales where the NEC sets the standard for wiring practices. At this low level of fault current, it may take a few seconds (UL943A states just under six seconds maximum) before the circuit is de-energized, but if the fault becomes more dangerous at 20 mA or higher the circuit is disconnected much faster.

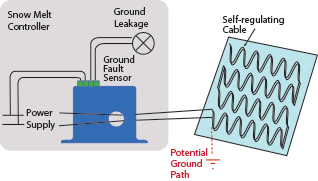

Underwriters Laboratories has established standards under UL943 for personnel protection (avoiding shock to humans) and also for equipment  protection at various fault levels and reaction time limits. The requirement for equipment protection is intended to keep a fault from damaging the machine more than to protect the operating personnel. Circuits supplying heating loads (heat strips, heat trace and snow melting equipment) are usually not disconnected until the fault current exceeds 30 mA or more. Electric vehicle charging stations have GFCI protection required, but the fault level is somewhere between standard personnel protection and the various levels of equipment protection, and not specified in the NEC. The NEC states the following:

protection at various fault levels and reaction time limits. The requirement for equipment protection is intended to keep a fault from damaging the machine more than to protect the operating personnel. Circuits supplying heating loads (heat strips, heat trace and snow melting equipment) are usually not disconnected until the fault current exceeds 30 mA or more. Electric vehicle charging stations have GFCI protection required, but the fault level is somewhere between standard personnel protection and the various levels of equipment protection, and not specified in the NEC. The NEC states the following:

Section 427.22

Ground-fault protection of equipment shall be provided for electric heat tracing and heating panels. This requirement shall not apply in industrial establishments where there is alarm indication of ground faults and the following conditions apply: (1) Conditions of maintenance and supervision ensure that only qualified persons service the installed systems. (2) Continued circuit operation is necessary for safe operation of equipment or processes.

Section 426.28

Ground-fault protection of equipment shall be provided for fixed outdoor electric devices and snow-melting equipment.

Section 555.3

The over current protective devices that supply marinas, boat yards, and commercial and noncommercial docking facilities shall have ground-fault protection not exceeding 30 mA.

There is no stated fault current limit in section 427.22 for heating equipment or 426.28 covering snow melt systems, but 555.3 for protection at docks clearly shows that the monitored circuit must be disconnected from the load if there is a fault over 30 mA.

The NEC calls for ground fault protection for very large systems, too.

Section 215.10

Ground-Fault Protection of Equipment. Each feeder disconnect rated 1000 amperes or more and installed on solidly grounded electrical systems of more than 150 volts to ground, but not exceeding 600 volts phase-to-phase, shall be provided with ground-fault protection of equipment in accordance with the provisions of 230.95.

Section 230.95

Ground-fault protection of equipment shall be provided for solidly grounded wye electric services of more than 150 volts to ground but not exceeding 1000 volts phase-to-phase for each service disconnect rated 1000 amperes or more. The grounded conductor for the solidly grounded wye system shall be connected directly to ground through a grounding electrode system, as specified in 250.50, without inserting any resistor or impedance device. The rating of the service disconnect shall be considered to be the rating of the largest fuse that can be installed or the highest continuous current trip setting for which the actual over current device installed in a circuit breaker is rated or can be adjusted. Exception: The ground-fault protection provisions of this section shall not apply to a service disconnect for a continuous industrial process where a non-orderly shutdown will introduce additional or increased hazards.

Setting

The ground-fault protection system shall operate to cause the service disconnect to open all ungrounded conductors of the faulted circuit. The maximum setting of the ground-fault protection shall be 1200 amperes, and the maximum time delay shall be one second for ground-fault currents equal to or greater than 3000 amperes.

The code continues to describe specifics regarding the testing of this equipment. In section 517.17 there are requirements for ground fault protection in hospitals and care facilities, whether the service is capable of supplying 1000 amps or not, and special requirements that must be met when there is a backup power source such as a generator.

The importance of protecting an electrical system against faults to earth cannot be overstated; the NEC sections referred to above are just the beginning of equipment protection. This type of fault sensing is not over current detection, so fusing or circuit breakers will keep the conductors or their insulation from being damaged.

There are a wide range of applications where ground fault detection is required, but if circuit size is reviewed, most personnel protection is needed for 15 or 20 amp circuits supplied at 120 volts. The requirements for equipment protection vary widely. This is where NK Technologies can provide a ground fault sensor with simple installation at the lowest cost. Rather than combining a detector with a circuit interrupter, the sensor provides contacts to open or close when a fault is detected. The contacts can be used to energize a shunt trip accessory on a circuit breaker, de-energize a contactor coil, or trigger an alarm if the process being monitored should only be stopped in an specific manner.

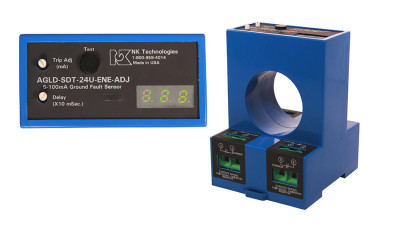

NK Technologies is proud to announce that the AGLD Series ground fault monitors are now UL listed under UL508. They have a sensing window large enough to monitor up to four 300 MCM THHN conductors, and have an easily adjustable trip point from 5 mA to 950 mA. The delay can also be set between zero and 10 seconds. Since the sensor is not a “circuit interrupter, “ it may not meet the latency requirements of the UL943 standards. The sensor would need to be tested by UL with each manufacturer’s circuit breaker or contactor individually to be accepted under these UL sections.

AGLD SERIES: Ground Fault Relay with Digital Display

AGLD Series ground fault sensors keep machinery and their operators safe from accidental shocks. The large, one piece solid-core design allows for installation over wires feeding heavy loads. The output relay will change state at any point between 5 mA and 100 mA, or 80 mA and 950 mA. The LED display will show the amount of fault current that will cause the output relay to change state. A delay can be set to allow down stream protection to activate before this sensor, keeping the main circuit protection hot and the equipment energized while the smaller faults are cleared.