Equipment Ground Fault Monitoring

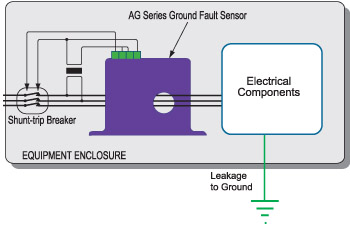

As we become more aware of occupational health and safety so the need for  protection against ground faults is growing. Industrial electrical equipment is fed via a distribution system which in turn is connected to a main feed. Ground fault protection may be installed, for instance at a main breaker, protecting the branch circuit but not necessarily a valuable or critical piece of equipment. Industrial Ground Fault Sensors from NK Technologies are designed to be installed in individual pieces of equipment or their electrical feed. The sensors provide an on/off output that may be used to operate a circuit interruption device like a shunt trip breaker or feed into an alarm system. With over 100 models to choose from, there’s sure to be one to fit your application.

protection against ground faults is growing. Industrial electrical equipment is fed via a distribution system which in turn is connected to a main feed. Ground fault protection may be installed, for instance at a main breaker, protecting the branch circuit but not necessarily a valuable or critical piece of equipment. Industrial Ground Fault Sensors from NK Technologies are designed to be installed in individual pieces of equipment or their electrical feed. The sensors provide an on/off output that may be used to operate a circuit interruption device like a shunt trip breaker or feed into an alarm system. With over 100 models to choose from, there’s sure to be one to fit your application.

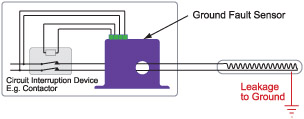

Insulation Breakdown

Industrial electrical heaters are prone to ground leakage due to the breakdown or contamination of insulators. The use of NK Technologies’ Ground Fault Sensors enables early detection of leakage Currents as small as 5mA. The on/off output of the sensor can be used to trigger a circuit interruption device (for example a shunt-trip breaker) or a monitoring device like a PLC to determine the required action. Latching and auto-reset models are available in both normally energized and normally de-energized configurations suitable for most applications.

contamination of insulators. The use of NK Technologies’ Ground Fault Sensors enables early detection of leakage Currents as small as 5mA. The on/off output of the sensor can be used to trigger a circuit interruption device (for example a shunt-trip breaker) or a monitoring device like a PLC to determine the required action. Latching and auto-reset models are available in both normally energized and normally de-energized configurations suitable for most applications.

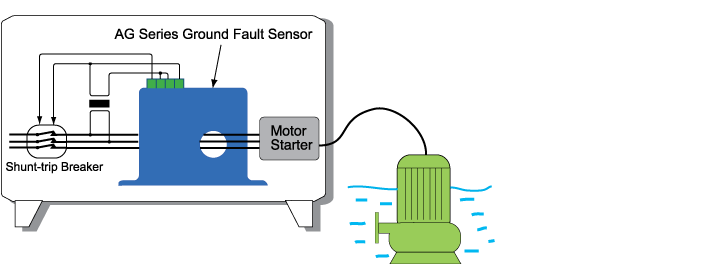

Moisture Ingress on a Submersible Pump Motor

An NK Technologies’ Ground Fault Sensor installed on a submersible pump motor provides  an easy to install replacement or addition to moisture sensors housed in the motor casing. Unlike moisture sensors that have to be wired back to the motor control center, the GF sensor is installed in the motor control center. By detecting the ground fault current resulting from moisture ingress or other potentially dangerous condition remedial action can be taken prior to catastrophic failure. Either the pump can be replaced at the next convenient time or switched off and a back-up pump started.

an easy to install replacement or addition to moisture sensors housed in the motor casing. Unlike moisture sensors that have to be wired back to the motor control center, the GF sensor is installed in the motor control center. By detecting the ground fault current resulting from moisture ingress or other potentially dangerous condition remedial action can be taken prior to catastrophic failure. Either the pump can be replaced at the next convenient time or switched off and a back-up pump started.

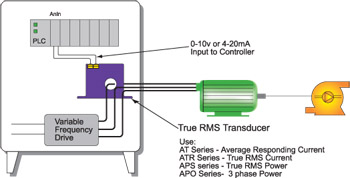

Pump Load Monitoring

NK Technologies’ Current Transducers are used to monitor motor current and  therefore motor load. The output from the transducer may be fed to an analog or digital indicator or a Programmable Logic Controller (PLC) for more sophisticated monitoring and control.

therefore motor load. The output from the transducer may be fed to an analog or digital indicator or a Programmable Logic Controller (PLC) for more sophisticated monitoring and control.

NK Technologies’ Power Transducers provide load monitoring in more critical applications where the addition of voltage measurement and the determination of the phase relationship between current and voltage (power factor) provides more control.

NK Technologies’ Ground Fault Sensors keep the pumps safe by measuring ground leakage currents as low as 5mA. This also provides an alternative to moisture sensors used with submersible pump motors.

Also see these other articles:

Pump Jam & Suction Loss

Moisture Ingress on a Submersible Pump Motor

Conveyor Jam Protection

When conveyors jam and the drive motor continues to run, expensive mechanical damage to the drive components often occurs. By installing an NK Technologies’ Current Operated Switch an overload condition, detected by higher than normal running amps, can be used to switch off power to the motor before mechanical damage results. The switch setting can be adjusted so it is not affected by normal changes in conveyor load. Current operated switches are the modern day equivalent of less reliable electromechanical jam relays that have been in use for many decades.

When conveyors jam and the drive motor continues to run, expensive mechanical damage to the drive components often occurs. By installing an NK Technologies’ Current Operated Switch an overload condition, detected by higher than normal running amps, can be used to switch off power to the motor before mechanical damage results. The switch setting can be adjusted so it is not affected by normal changes in conveyor load. Current operated switches are the modern day equivalent of less reliable electromechanical jam relays that have been in use for many decades.

In situations where there may be large variations in load an NK Technologies’ Current Transducer may be used to feed motor amps to the conveyor control system, commonly a PLC. The PLC may be programmed to accommodate different setpoints for different mechanical loads so that jam protection is provided from light to heavy loads. In situations where the conveyor is not able to accept analog signals NK Technologies has developed a patented transducer with a frequency output suitable for the Digital Inputs of most PLCs.

Fan Status: Independent Verification of Operation

By adjusting the setpoint pump coupling or fan belt failure can be detected. This reliable solid-state solution eliminates the need for unreliable pressure current switches and their costly installation.