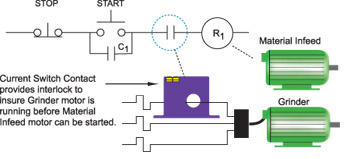

Safety Interlocks

NK Technologies’ Current Operated Switches are available in models that will  switch at measured currents from just a few milliamps (mA) to over 100 amps. Detecting current flow is the definitive measurement to determine if equipment is on or off, a motor is running or not, a heater is on or off etc. NK’s Current Switch products are installed for interlocking for operational and safety purposes.

switch at measured currents from just a few milliamps (mA) to over 100 amps. Detecting current flow is the definitive measurement to determine if equipment is on or off, a motor is running or not, a heater is on or off etc. NK’s Current Switch products are installed for interlocking for operational and safety purposes.

Drill/Tool Status

Automated drilling machines usually provide fast and accurate holes, that is until  the drill bit breaks. The last thing a high production furniture manufacturer wanted to do is to keep drilling parts with one hole missing! NK Technologies’ Current Operated Switches were installed over the current carrying conductor feeding the drill motor and when the amperage dropped below a preset level a signal was sent to the controller to stop operation so that the drill bit could be changed. NK’s range of current transducers are used in a variety of applications on machine tools to detect status.

the drill bit breaks. The last thing a high production furniture manufacturer wanted to do is to keep drilling parts with one hole missing! NK Technologies’ Current Operated Switches were installed over the current carrying conductor feeding the drill motor and when the amperage dropped below a preset level a signal was sent to the controller to stop operation so that the drill bit could be changed. NK’s range of current transducers are used in a variety of applications on machine tools to detect status.

Welder Tip Dressing

Motor-driven tip dressers are used in conjunction with robotic resistance

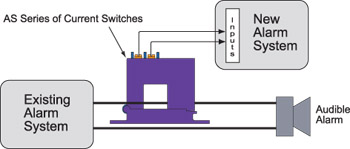

Isolated Alarm System Interfacing

If an alarm or monitoring system is to be installed adjacent to another, (for

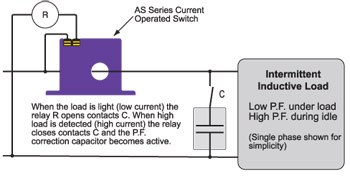

Power Factor Correction Control

With ever increasing demands for electrical power the power generating

Power Transformer Monitoring

Installing an NK Technologies’ Current Transducer over the conductors on the

Most large power transformers utilize auxiliary cooling fans, drawing cooler air from a distance away from the transformer. NK Technologies’ Current Transducers or Current Operated Switches are used to monitor these fans for overload from bearing failure, under loads from drive component breakage or slippage, and to just be sure that the fan is energized and doing its required job.

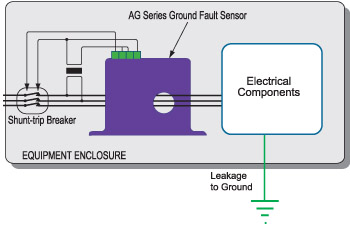

Equipment Ground Fault Monitoring

As we become more aware of occupational health and safety so the need for

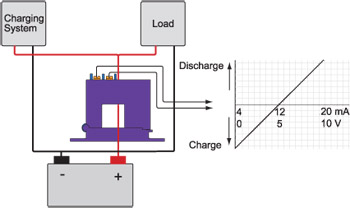

Battery Charging System

Industrial re-chargeable battery systems are used to provide primary power for

- Terminals can rise to the potential of the DC circuit.

- The signal produced is usually 50 – 100mV at full rated current and must be isolated and amplified to a higher level signal (typically 4-20mA) to be of use to an industrial monitoring or control system.

- The shunt dissipates power according to the square of the current flowing through it. This manifests itself as a loss of power or an insertion loss.

Forget the shunt and instead simply pass the current carrying conductor through the aperture of an NK Technologies’ DC Current Transducer. There is no insertion loss and the 4-20mA signal is fully isolated from both the DC current being measured and the power supply. The bipolar option also accommodates the change in direction of current flow.

Generator Installations

The need for back-up power for critical loads is becoming more and more

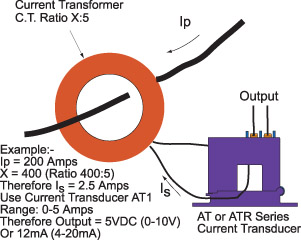

Current Transformer Monitoring

C.T.s (Current Transformers) have been used for many years to measure AC

C.T.s step down current and the secondary has to feed into a very low impedance to maintain accuracy. In the event that the secondary is open-circuited during operation the device operates as a step-up voltage transformer since there is nowhere for the current to flow and voltages of several kV appear on the secondary, overheating occurs and combustion or explosion often results. NK Technologies’ Split-Core Current Transducers are simply and safely snapped over the shorted secondary of a C.T. to provide a fully isolated analog 4-20mA DC signal proportional to the current in the secondary, which in turn is proportional to the measured (primary) current.

NK’s Split-core Current Transducers are used to safely monitor the secondary of high voltage C.T.s used in power generation and distribution in the low voltage cubicles.