Closed Loop Control

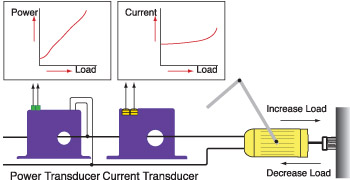

Normal linear AC induction motors have a current characteristic that increases with

At an engine block manufacturing facility NK Technologies’ Current Transducers provide the input to a PLC used to position the rotating wire brushes in order to clean away burrs and debris after machining. As the current, and thus the load, changes so the brushes are positioned for optimal clean-up. Similarly Power Transducers are used to control the position of wheel wash brushes in a carwash. Power measurement provides a more linear relationship for motors and other loads with non-linear current characteristics. Current Operated Switches are used to co-ordinate operations between conveyor, washing and drying systems.

DC Motor Installations

Many applications requiring high torque at low speeds, like bridge cranes and log

Crusher/Grinder/Shredder Motor Interlocks

- Help prevent jamming

- Improve the uniformity of the resultant product

- Enhance overall production efficiency

By installing an NK Technologies’ Current Transducer or Power Transducer to monitor the in-feed to a crushing process, the speed of the in feed drive can be slowed when the crushing motor is working too hard, or the speed can be increased when the crusher is under worked. The analog 4-20mA proportional signal is fed directly into a VFD, and the drive does the rest of the control.

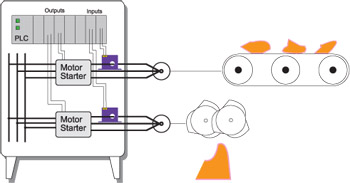

Additionally, NK Technologies’ Current Operated Switches installed on other conveying motors can be used to signal malfunction (for example over-load or motor failure) to help prevent costly equipment damage.

NK technologies current sensors come in a variety of configurations for quick and simple installation either for the OEM or End-User.

Conveyor Jam Protection

In situations where there may be large variations in load an NK Technologies’ Current Transducer may be used to feed motor amps to the conveyor control system, commonly a PLC. The PLC may be programmed to accommodate different setpoints for different mechanical loads so that jam protection is provided from light to heavy loads. In situations where the conveyor is not able to accept analog signals NK Technologies has developed a patented transducer with a frequency output suitable for the Digital Inputs of most PLCs.