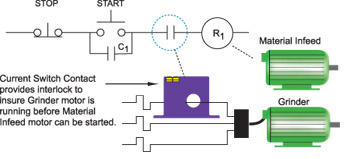

Safety Interlocks

NK Technologies’ Current Operated Switches are available in models that will  switch at measured currents from just a few milliamps (mA) to over 100 amps. Detecting current flow is the definitive measurement to determine if equipment is on or off, a motor is running or not, a heater is on or off etc. NK’s Current Switch products are installed for interlocking for operational and safety purposes.

switch at measured currents from just a few milliamps (mA) to over 100 amps. Detecting current flow is the definitive measurement to determine if equipment is on or off, a motor is running or not, a heater is on or off etc. NK’s Current Switch products are installed for interlocking for operational and safety purposes.

Drill/Tool Status

Automated drilling machines usually provide fast and accurate holes, that is until  the drill bit breaks. The last thing a high production furniture manufacturer wanted to do is to keep drilling parts with one hole missing! NK Technologies’ Current Operated Switches were installed over the current carrying conductor feeding the drill motor and when the amperage dropped below a preset level a signal was sent to the controller to stop operation so that the drill bit could be changed. NK’s range of current transducers are used in a variety of applications on machine tools to detect status.

the drill bit breaks. The last thing a high production furniture manufacturer wanted to do is to keep drilling parts with one hole missing! NK Technologies’ Current Operated Switches were installed over the current carrying conductor feeding the drill motor and when the amperage dropped below a preset level a signal was sent to the controller to stop operation so that the drill bit could be changed. NK’s range of current transducers are used in a variety of applications on machine tools to detect status.

Welder Tip Dressing

Motor-driven tip dressers are used in conjunction with robotic resistance

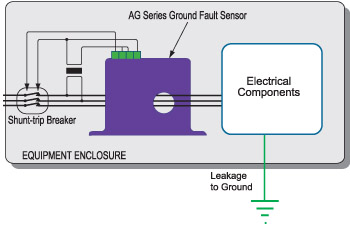

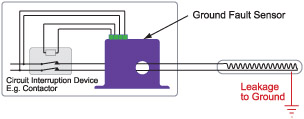

Equipment Ground Fault Monitoring

As we become more aware of occupational health and safety so the need for

Ground Fault Monitoring on Heat Trace Systems

Heat trace cable is used to keep pipes or their contents from freezing, or to keep

Insulation Breakdown

Industrial electrical heaters are prone to ground leakage due to the breakdown or

Pump Load Monitoring

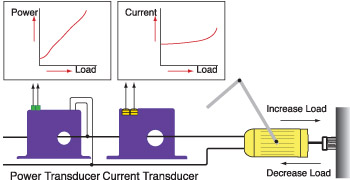

NK Technologies’ Current Transducers are used to monitor motor current and

NK Technologies’ Power Transducers provide load monitoring in more critical applications where the addition of voltage measurement and the determination of the phase relationship between current and voltage (power factor) provides more control.

NK Technologies’ Ground Fault Sensors keep the pumps safe by measuring ground leakage currents as low as 5mA. This also provides an alternative to moisture sensors used with submersible pump motors.

Also see these other articles:

Pump Jam & Suction Loss

Moisture Ingress on a Submersible Pump Motor

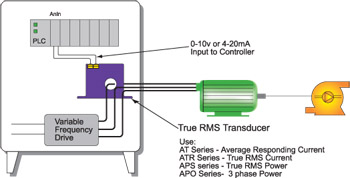

Closed Loop Control

Normal linear AC induction motors have a current characteristic that increases with

At an engine block manufacturing facility NK Technologies’ Current Transducers provide the input to a PLC used to position the rotating wire brushes in order to clean away burrs and debris after machining. As the current, and thus the load, changes so the brushes are positioned for optimal clean-up. Similarly Power Transducers are used to control the position of wheel wash brushes in a carwash. Power measurement provides a more linear relationship for motors and other loads with non-linear current characteristics. Current Operated Switches are used to co-ordinate operations between conveyor, washing and drying systems.

Conveyor Jam Protection

In situations where there may be large variations in load an NK Technologies’ Current Transducer may be used to feed motor amps to the conveyor control system, commonly a PLC. The PLC may be programmed to accommodate different setpoints for different mechanical loads so that jam protection is provided from light to heavy loads. In situations where the conveyor is not able to accept analog signals NK Technologies has developed a patented transducer with a frequency output suitable for the Digital Inputs of most PLCs.