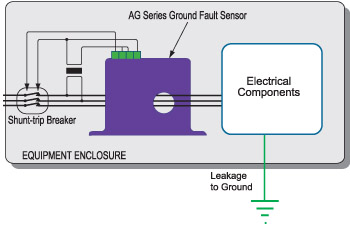

Equipment Ground Fault Monitoring

As we become more aware of occupational health and safety so the need for

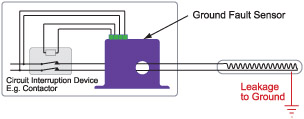

Insulation Breakdown

Industrial electrical heaters are prone to ground leakage due to the breakdown or

DC Motor Installations

Many applications requiring high torque at low speeds, like bridge cranes and log

Conveyor Jam Protection

In situations where there may be large variations in load an NK Technologies’ Current Transducer may be used to feed motor amps to the conveyor control system, commonly a PLC. The PLC may be programmed to accommodate different setpoints for different mechanical loads so that jam protection is provided from light to heavy loads. In situations where the conveyor is not able to accept analog signals NK Technologies has developed a patented transducer with a frequency output suitable for the Digital Inputs of most PLCs.