Power Factor Correction Control

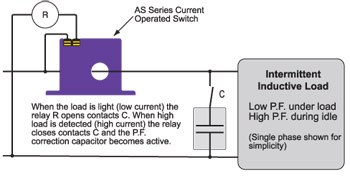

With ever increasing demands for electrical power the power generating  companies are beginning to penalize customers with low Power Factors. Low PFs can be considered very inefficient use of electrical energy. A low PF can be corrected by the installation of PF Correction capacitors. Although this can be achieved at the main feeder most facilities, due to multiple varying loads, choose to install PF correction on individual pieces of equipment (like a large motor) or area of plant. When a load is switched off, unless the PF correction capacitors are removed, undesirable over-correction occurs. Sophisticated automatic control systems are available but are very expensive. A simple way to switch a PF correction capacitor bank is to use an NK Technologies’ Current Operated Switch. When the load goes down, for example at night when equipment is not used, the PF correction capacitor is switched out. Then when load returns it is switched back in.

companies are beginning to penalize customers with low Power Factors. Low PFs can be considered very inefficient use of electrical energy. A low PF can be corrected by the installation of PF Correction capacitors. Although this can be achieved at the main feeder most facilities, due to multiple varying loads, choose to install PF correction on individual pieces of equipment (like a large motor) or area of plant. When a load is switched off, unless the PF correction capacitors are removed, undesirable over-correction occurs. Sophisticated automatic control systems are available but are very expensive. A simple way to switch a PF correction capacitor bank is to use an NK Technologies’ Current Operated Switch. When the load goes down, for example at night when equipment is not used, the PF correction capacitor is switched out. Then when load returns it is switched back in.

Equipment Ground Fault Monitoring

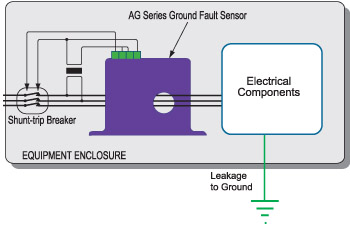

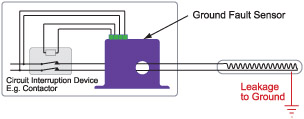

As we become more aware of occupational health and safety so the need for  protection against ground faults is growing. Industrial electrical equipment is fed via a distribution system which in turn is connected to a main feed. Ground fault protection may be installed, for instance at a main breaker, protecting the branch circuit but not necessarily a valuable or critical piece of equipment. Industrial Ground Fault Sensors from NK Technologies are designed to be installed in individual pieces of equipment or their electrical feed. The sensors provide an on/off output that may be used to operate a circuit interruption device like a shunt trip breaker or feed into an alarm system. With over 100 models to choose from, there’s sure to be one to fit your application.

protection against ground faults is growing. Industrial electrical equipment is fed via a distribution system which in turn is connected to a main feed. Ground fault protection may be installed, for instance at a main breaker, protecting the branch circuit but not necessarily a valuable or critical piece of equipment. Industrial Ground Fault Sensors from NK Technologies are designed to be installed in individual pieces of equipment or their electrical feed. The sensors provide an on/off output that may be used to operate a circuit interruption device like a shunt trip breaker or feed into an alarm system. With over 100 models to choose from, there’s sure to be one to fit your application.

Insulation Breakdown

Industrial electrical heaters are prone to ground leakage due to the breakdown or

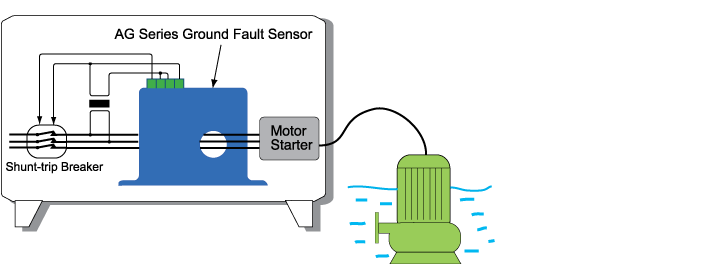

Moisture Ingress on a Submersible Pump Motor

An NK Technologies’ Ground Fault Sensor installed on a submersible pump motor provides

Saw Load Monitoring

A similar arrangement can be used with circular saws. The blades become brittle after excessive heating if they are worked too hard. Many automatic systems are in use whereby the current draw is used to reduce the motor load typically by reducing the feed-rate.