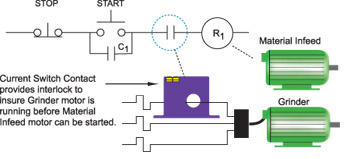

Safety Interlocks

NK Technologies’ Current Operated Switches are available in models that will  switch at measured currents from just a few milliamps (mA) to over 100 amps. Detecting current flow is the definitive measurement to determine if equipment is on or off, a motor is running or not, a heater is on or off etc. NK’s Current Switch products are installed for interlocking for operational and safety purposes.

switch at measured currents from just a few milliamps (mA) to over 100 amps. Detecting current flow is the definitive measurement to determine if equipment is on or off, a motor is running or not, a heater is on or off etc. NK’s Current Switch products are installed for interlocking for operational and safety purposes.

Welder Tip Dressing

Motor-driven tip dressers are used in conjunction with robotic resistance  welders in a manufacturing area like an automobile body assembly plant. Essentially they are like large pencil sharpeners and they require regular maintenance. After maintenance the dressers are not always switched back on, so that when the robotic welder requests tip sharpening, the tips are not dressed and poor quality welds result, which in turn produces poor quality panels. By installing an NK Technologies’ Current Operated Switch on the tip dresser the status is signaled and an alarm is generated to warn if the dresser remains un-powered and offline. NK’s unique split-core packaging is ideal for retrofit installation and the compact solid-core unit is well suited for OEM applications.

welders in a manufacturing area like an automobile body assembly plant. Essentially they are like large pencil sharpeners and they require regular maintenance. After maintenance the dressers are not always switched back on, so that when the robotic welder requests tip sharpening, the tips are not dressed and poor quality welds result, which in turn produces poor quality panels. By installing an NK Technologies’ Current Operated Switch on the tip dresser the status is signaled and an alarm is generated to warn if the dresser remains un-powered and offline. NK’s unique split-core packaging is ideal for retrofit installation and the compact solid-core unit is well suited for OEM applications.

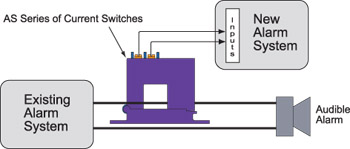

Isolated Alarm System Interfacing

If an alarm or monitoring system is to be installed adjacent to another, (for

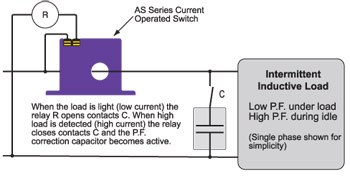

Power Factor Correction Control

With ever increasing demands for electrical power the power generating

Power Transformer Monitoring

Installing an NK Technologies’ Current Transducer over the conductors on the

Most large power transformers utilize auxiliary cooling fans, drawing cooler air from a distance away from the transformer. NK Technologies’ Current Transducers or Current Operated Switches are used to monitor these fans for overload from bearing failure, under loads from drive component breakage or slippage, and to just be sure that the fan is energized and doing its required job.

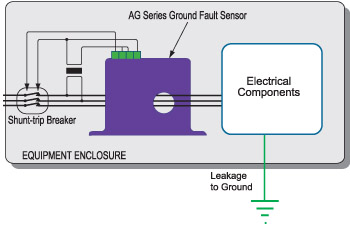

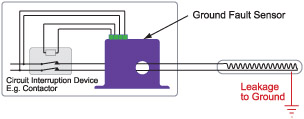

Equipment Ground Fault Monitoring

As we become more aware of occupational health and safety so the need for

Generator Installations

The need for back-up power for critical loads is becoming more and more

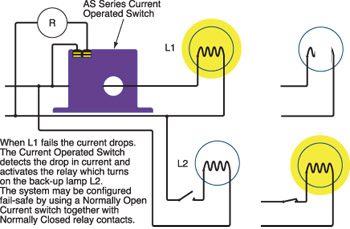

Lamp Failure Detection

The simple addition of an NK Technologies’ Current Operated Switch in a

Insulation Breakdown

Industrial electrical heaters are prone to ground leakage due to the breakdown or

Vacuum Pump Monitor

Vacuum pumps are used in a variety of applications in the semiconductor industry,