Equipment Ground Fault Monitoring

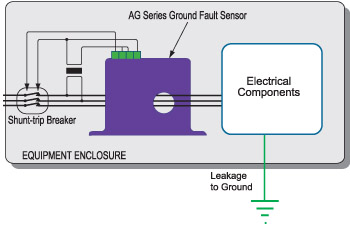

As we become more aware of occupational health and safety so the need for  protection against ground faults is growing. Industrial electrical equipment is fed via a distribution system which in turn is connected to a main feed. Ground fault protection may be installed, for instance at a main breaker, protecting the branch circuit but not necessarily a valuable or critical piece of equipment. Industrial Ground Fault Sensors from NK Technologies are designed to be installed in individual pieces of equipment or their electrical feed. The sensors provide an on/off output that may be used to operate a circuit interruption device like a shunt trip breaker or feed into an alarm system. With over 100 models to choose from, there’s sure to be one to fit your application.

protection against ground faults is growing. Industrial electrical equipment is fed via a distribution system which in turn is connected to a main feed. Ground fault protection may be installed, for instance at a main breaker, protecting the branch circuit but not necessarily a valuable or critical piece of equipment. Industrial Ground Fault Sensors from NK Technologies are designed to be installed in individual pieces of equipment or their electrical feed. The sensors provide an on/off output that may be used to operate a circuit interruption device like a shunt trip breaker or feed into an alarm system. With over 100 models to choose from, there’s sure to be one to fit your application.

UV & IR Lamp Status Monitoring

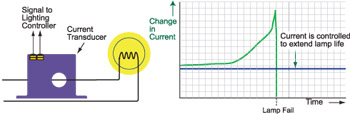

Ultraviolet (UV) lamps are used commonly to disinfect water by killing bacteria. High Intensity Infra Red (IR) lamps are used in a variety of industrial processes to provide heat both for drying and curing processes. Correct operation is very important and can be determined by measuring current draw. Using an NK Technologies’ Current Operated Switch provides simple and quick verification. The on/off contacts of the switch may be used to simply indicate status to an operator using a lamp or wired to the input of a PLC preprogrammed with the necessary corrective action. Alternatively, NK’s Current Transducers may be used to provide an accurate measurement of the current draw by a UV, IR or other light source.

High Intensity Infra Red (IR) lamps are used in a variety of industrial processes to provide heat both for drying and curing processes. Correct operation is very important and can be determined by measuring current draw. Using an NK Technologies’ Current Operated Switch provides simple and quick verification. The on/off contacts of the switch may be used to simply indicate status to an operator using a lamp or wired to the input of a PLC preprogrammed with the necessary corrective action. Alternatively, NK’s Current Transducers may be used to provide an accurate measurement of the current draw by a UV, IR or other light source.

Critical Lighting Systems Preventative Maintenance

High technology lamps have been developed for a variety of specialized

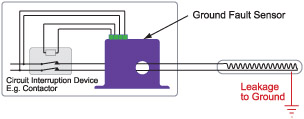

Insulation Breakdown

Industrial electrical heaters are prone to ground leakage due to the breakdown or

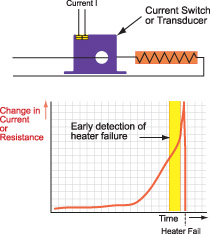

Heater Life Prediction

As an electric heating element ages, its resistance also changes. Many high

Status Alarming

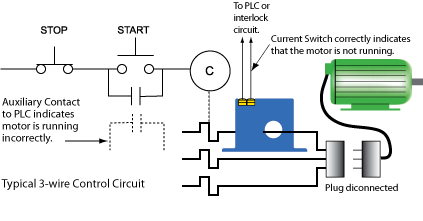

The auxiliary contacts in a motor starter are commonly used to indicate when the

At a large fish farm, failed aerator pumps resulted in massive stock losses. Because the auxiliary contacts remained closed when the pump failed, the alarm was never activated, the back-up pumps were not switched on and the fish suffocated due to lack of oxygen. Now NK Technologies’ Current Operated Switches have been installed to provide an alarm signal and a signal to automatically switch over to the back-up aerator pumps.

Closed Loop Control

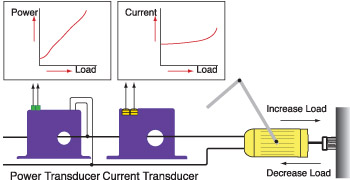

Normal linear AC induction motors have a current characteristic that increases with

At an engine block manufacturing facility NK Technologies’ Current Transducers provide the input to a PLC used to position the rotating wire brushes in order to clean away burrs and debris after machining. As the current, and thus the load, changes so the brushes are positioned for optimal clean-up. Similarly Power Transducers are used to control the position of wheel wash brushes in a carwash. Power measurement provides a more linear relationship for motors and other loads with non-linear current characteristics. Current Operated Switches are used to co-ordinate operations between conveyor, washing and drying systems.

DC Motor Installations

Many applications requiring high torque at low speeds, like bridge cranes and log

Conveyor Jam Protection

In situations where there may be large variations in load an NK Technologies’ Current Transducer may be used to feed motor amps to the conveyor control system, commonly a PLC. The PLC may be programmed to accommodate different setpoints for different mechanical loads so that jam protection is provided from light to heavy loads. In situations where the conveyor is not able to accept analog signals NK Technologies has developed a patented transducer with a frequency output suitable for the Digital Inputs of most PLCs.