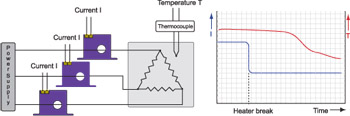

Heater Failure Detection

For 3-phase heaters installing an NK Technologies’ Current Transducer on each leg of a delta connected heating array is the best way to detect loss of one element. Unlike a typical induction motor, there will not be a substantial change in the current draw of the two adjacent phases when a heating element open circuits. The load has disappeared, and the work of heating will not be shared by the other elements. There will be a reduction in thermal output, which can take quite some time to detect with temperature sensors like thermocouples. A current transducer will identify the problem in milliseconds! Poor product quality can be prevented and large quantities of raw material can be saved by quick action.