Mitigation of faults is something that all facilities must work to achieve, not only for the safety of the people working in the plant but to reduce the damage when a fault to earth occurs. There is no insulating material available at the present time that is both flexible and does not degrade over time due to environmental conditions. Oil, greases, water and other contaminates are the most common causes of deterioration of wire insulation, but excessive heat, ultraviolet radiation and voltage spikes are also major contributors. In any case, failing insulation creates short circuits from phase to phase or from phase to earth. Electrical faults to earth are by far the most common cause of motor failure according to EASA, the Electric Apparatus Service Association.

Mitigation of faults is something that all facilities must work to achieve, not only for the safety of the people working in the plant but to reduce the damage when a fault to earth occurs. There is no insulating material available at the present time that is both flexible and does not degrade over time due to environmental conditions. Oil, greases, water and other contaminates are the most common causes of deterioration of wire insulation, but excessive heat, ultraviolet radiation and voltage spikes are also major contributors. In any case, failing insulation creates short circuits from phase to phase or from phase to earth. Electrical faults to earth are by far the most common cause of motor failure according to EASA, the Electric Apparatus Service Association.

There are many locations in the workplace where ground fault protection is required to keep personnel from shock hazards, including bathrooms and break/kitchen areas. Ground fault protection is also required where electrical heating elements are used to treat metal parts or other manufacturing processes. The heating process is often accomplished with three phase power. Because the process is located where personnel have little access, the National Electric Code allows for more current to earth before the circuit is de-energized than what is allowed in bathrooms and kitchens. The conditions in heating applications are very often three phase, and can draw more current than 15 or 20 amps. Heaters do not plug into an outlet like most GFCI protected equipment does.

Protecting submersible pumps in fountains and around pools against ground faults is also required by the National Electric Code. While products are readily available to detect faults to earth in these applications, if the pump is driven with a variable frequency drive, monitoring the load side circuit of the drive is quite difficult due to the carrier or switching frequency of the controller used to modify the output.

The engineers at NK Technologies have solved this problem. By studying the output from a pulse width modulated variable speed drive, algorithms were developed to detect only current flowing to ground by filtering out the extraneous noise and distortion inherent in the power supplied from a variable frequency drive.

The AGV series earth leakage relays can be set to trip at three field selectable points: 30, 50 or 100 mA. A delay of up to 10 seconds to the output contact action can also be added. Some drives cause zero sequence detection devices to trip when they first start; adding a delay will allow the relay to pause until this condition dissipates, but still react quickly enough to keep the equipment from being damaged.

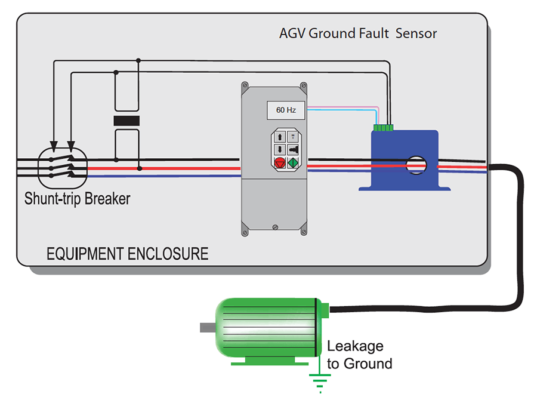

The relays can be configured so the output relay changes state only when there is a fault detected (-DEN) or when a fault occurs, or the power is removed from the relay (-ENE), as either can be used to operate the solenoid of a shunt trip breaker. The latching (-LA) models only trip when a fault is detected, and are commonly suggested when the contact is used to de-energize a contactor coil.

AGV Series

Ground Fault (Earth Leakage) Relay

AGV Series Ground Fault Detectors help protect products and processes from damage due to ground fault conditions by monitoring all current-carrying conductors in grounded single- and three-phase delta or wye systems.