Electrical systems vary widely all over the world. Most of the power transmission is high voltage AC, but there are a

To make it easier to measure and monitor both AC or DC voltage, NK Technologies offers sensors that convert the voltage (potential) to low level analog output signals that can be read and understood by panel meters, data acquisition systems or programmable logic controllers. These sensors can be used in a number of applications.

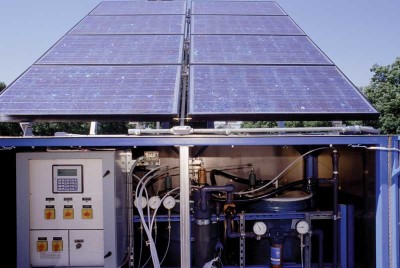

Photovoltaic (solar) panels produce low voltage DC. This is usually converted to AC for localized use, but grid connected systems are also prevalent and growing in areas where the utility allows it. The larger the photovoltaic (PV) array, the more likely the DC voltage to the inverter will be 1000 volts or higher. Monitoring the voltage level can be very helpful whether to confirm that a PV panel is producing the power it should be producing.

In many industries DC motors are installed and perform most of the heaviest lifting. They are powered with DC voltages of 700-750 VDC. By varying the voltage applied to the field windings, the speed can be changed. Monitoring the voltage can ensure that the DC motor voltage does not fall to a point of stalling the motor rotation.

NK Technologies offers voltage transducers with ranges from 0–800 to 0–1200 volts, and outputs of 4–20mA, 0–5 or 0–10VDC, all proportional to the connected voltage with +/-1% of full scale. These sensors attach easily to a DIN rail or screwed to a back panel for easy installation.

VTU Series High Voltage DC/AC Voltage Transducer

The VTU series of voltage transducers provide very high accuracy and safety in a panel or DIN rail mounted housing. One sensor design can measure DC or AC circuit voltages to 1200 volts, and produce an analog signal directly proportional to the voltage connected. When the voltage is AC, the output signal will be proportional to the RMS voltage.

This valuable information can be used to spot issues with power generation (conventional and alternative sources) like brown outs and phase loss. The voltage will be present on the line side of a disconnect even when the breaker or switch is open.