From the first one-piece current operated switch designed by NK Technologies in the early 1980’s, the magnitude of current needed to create a change in the output contact was set using a potentiometer, turned while the circuit was energized. The new ASC AC current operated switch is designed with a digital processor instead of the manual potentiometer adjustment and is factory calibrated eliminating the need to set the trip point in the field. This reduces the time it takes to install the sensor and results in a significant cost savings. It also removes the possibility that the set point will drift from thermal expansion and contraction due to changing environmental conditions. Improved reliability and a reduction in alarms is the end result which is critical in many applications.

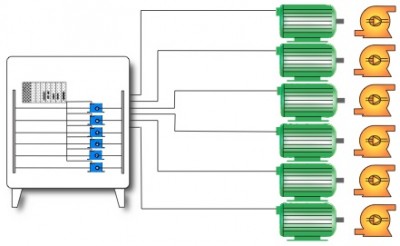

Air Handling Fan Protection: Factory-set trip points are ideal when there are several loads, all using the same motor to drive the fan blades.

For example, a manufacturer of heat treating equipment and control systems uses current operated switches to confirm that the heating elements are energized. While they could use an auxiliary mechanical interlock contact on the contactor, interlocks can fail resulting in the interlock contact welding closed and producing a false indication that the element is working when the contactor is open. Using a current sensor has proven to be a low cost solution that is more reliable. The current draw of each element is calculated and confirmed with testing, with higher wattage demand types using more current than lower demand types. Using a current sensor set to close at the level each element draws saves time during the control panel set up and commissioning. Installing a current switch over the conductor feeding the heating element is easy; all that is required is to connect the power from the controller to the switch terminal and back to the controller. Once the wire passes through the current switch sensing window, the solid-state contact closes as current rises to the predetermined magnitude.

For an OEM of refrigeration compressors, the sensor can be installed quickly and before the control panel is energized. The final test of the equipment can be completed with the control panel door closed. This helps protect personnel by eliminating the need to adjust the sensor trip point while the compressor is running. Reduced installation time and higher accuracy help keep costs down. Providing a sensor which does not need to be adjusted when there is a hot wire inches from a screwdriver improves the safety of the installation far beyond what has been possible in the past.

ASC Series Factory Calibrated Switches Reduce Installation Cost and Make Current Monitoring More Accurate

ASC Series Current Operated Switches are precision calibrated at the factory per customers' specifications and guaranteed within 1% accuracy. Because the switch is factory calibrated eliminating the need to turn the potentiometer to the correct position in the field, installation time is substantially reduced resulting in a significant cost savings. The ASC combines a current transformer, signal conditioner and limit alarm into a single package for use in status monitoring or proof of operation applications and is perfect for OEM applications where the need for a limit alarm is required. Available in a solid-core or a split-core case to maximize ease of installation.