New Limit Switch with Single Turn Potentiometer and Digital Display Provides Greater Accuracy and Easy Installation

Current limit switches can be used to trigger an alarm or an action when current exceeds a specific level, or falls below the  normal running current. The design of most limit switches requires the installer to adjust the trip point while the monitored load is energized, or often leaves the adjustment at the minimum so the contact closes at any amount of current.

normal running current. The design of most limit switches requires the installer to adjust the trip point while the monitored load is energized, or often leaves the adjustment at the minimum so the contact closes at any amount of current.

The latest AC current sensor from NK Technologies utilizes a revolutionary approach to adjust the trip point of an alarm contact. With power supplied to the sensor, a three digit LED display is activated. A potentiometer on the top of the sensor is turned, and the display changes to show the amount of current needed to actuate the contact. The trip point can be set before the monitored circuit is energized, making this approach far safer than other designs. This method not only adds a large measure of safety to the installation, it is inherently more precise and can be done very quickly. Simply energize the monitored load and measure the current used under normal running conditions, after inrush. Power off the load, and turn the switch adjustment to a point just over or under the normal reading, depending on the application. Any adjustments made by unauthorized personnel will be displayed, further improving overall system reliability.

A limit switch is ideal for use in many industrial applications:

Conveyors: Use the alarm contact to de-energize a magnetic starter coil to keep an overload caused by a jam from doing significant damage.

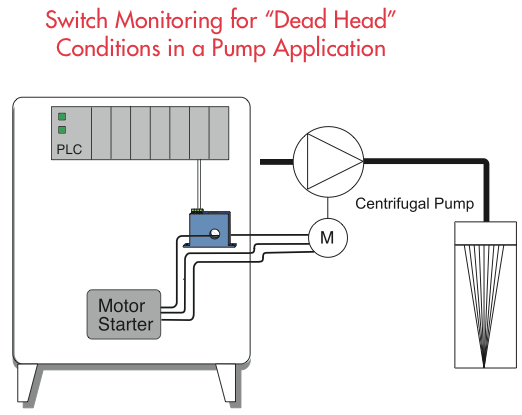

Pumps: Adjust the contact so an under-current condition is detected. Under-current can be caused by dead head or open discharge line.

Fan Handling: A current switch is used to detect normal running conditions, providing a contact change if the current falls below normal, such as when a drive belt breaks or a coupling is sheared. Installation is much faster and more reliable than using differential pressure switches and requires no duct penetrations.

New ASD Current Operated Limit Switch From NK Technologies

ASD series sensors provide a limit alarm contact with the easiest adjustment method ever designed. The single turn potentiometer, allows the trip point to be set before the sensor is installed, or before the monitored circuit is energized. The LED display provides a quick visual indication of where the contact changes. The trip point is adjustable from 2% to 100% of the analog range, and can be verified at any time by viewing the LCD display on the sensor.