The two most practical methods used to monitor the DC current produced are current shunts and Hall element based sensors.

In contrast, using a current transducer with a Hall element design removes the need to cut or strip the conductor, or disturb wiring at all when installing split core models. A DC current transducer with temperature compensation provides accurate current measurement whether the measurement point is in a very warm area or subject to freezing temperatures; the sensor output will remain accurate. There is no need to attempt to compensate for the temperature changes when programming the controller.

When the sensors are used to monitor the output of photovoltaic panels, they have the same accuracy whether they are installed in the enclosure outdoors near the panels or inside where the temperature remains relatively constant. Measuring the DC current output from PV panels is one of the most common uses for this type of transducer. In many installations the controllers are mounted on the roof of the building or along side the earth mounted collectors. Because the sensor works twenty four hours a day, the temperature can rise and fall dramatically.

DC current transducers are also used to monitor small DC motors in conveyors and positioning equipment and large DC motors in cranes, welding equipment, and equipment used in the wood products industry. In industrial environments, the ambient temperature is seldom controlled and the control cabinets can be subject to the high heat of summer and the bitter cold of winter. Using a sensor designed to compensate for extreme temperature fluctuations means an accurate measurement regardless of the season.

The New Patent-Pending DT Series Current Transducer with Temperature Compensation Provides Accurate Measurement Even in Extreme Temperatures

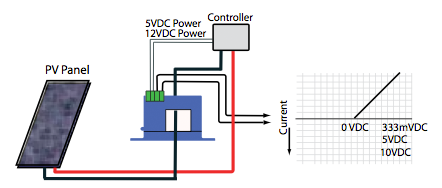

NK Technologies’ new DT Series Current Transducer with Temperature Compensation has a very stable and highly accurate output at broad temperature extremes; industry standard output signals with high levels of noise immunity; and complete isolation from the monitored circuit. These features save installation time, reduce the number of components required and make the installation very reliable and safe for inspectors or maintenance personnel. These models are single range, take less panel space in combiner or re-combiner boxes, and produce an output of your choice: 333m VDC (powered by either 5 VDC or 12 VDC), 0–5 VDC and 0–10 VDC (powered with 12 VDC) to match the controller or data logger you select. The 333 mVDC output is often used for power monitoring applications. There is much less than 0.1% drift in the output due to ambient temperature extremes between -20°C and +50°C. The DT Series has set the standard for accuracy at broad temperature extremes.