Many industrial processes use electrically powered heat trace systems. Installers with little experience in this application think that heat trace cable is used to keep water pipes from freezing, but this is just the beginning. Heat trace is also used extensively to keep product being transferred from one process to another, through piping, at a constant temperature. This helps to keep the material liquid, or at least the same viscosity, during the transfer. Allowing the product to cool even slightly can cause unwanted chemical reactions. There are other ways to accomplish the same task. Commonly steam is injected at low pressure into a separate tube attached to the pipe that needs to stay at a constant temperature. Heated air can be used to perform the required function in certain applications where electrically heated cable or steam trace may be dangerous or impractical. Installation is quite expensive in both forced air and steam heat.

Electrically operated heat trace cable has a number of advantages over these other methods:

Electrically operated heat trace cable has a number of advantages over these other methods:

* Electrical circuits can be extended for extremely long distances without much degradation, whereas steam or forced air cools rapidly as it travels away from the heat source.

* Most electricians can install cable but steam requires expert pipe fitters using a great deal of planning and time. Forced air systems are most effective in smaller, more confined areas. They also require ducting, a heat source (gas, fuel or electric) and electrical power to operate the fans at each point.

* Cable is more flexible, allowing for changes in ambient temperature to affect the installation to a smaller degree, without the need for pipe expansion joints as would be needed with steam systems.

The primary purpose for monitoring electric heat trace cable is so “leaks” can be detected before they cause irreparable harm. If steam or heated air leaks from a pipe, there may be some damage caused by excessive heat pressure or corrosion, but leaking electricity has the potential to kill. A maintenance person wearing gloves and boots will be fairly well protected against shock but it’s certainly not worth taking any chances.

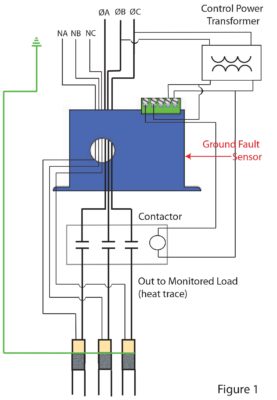

The most common installations use a cable connecting one phase to neutral or one phase to another phase. If both current carrying conductors pass through an NK Technologies’ ground fault relays, the magnetic field produced by the AC current in one conductor will be cancelled out by the return current in the other conductor. Over time when the cable insulation begins to break down or is damaged and the conductor is exposed, there will be some current passing to ground. When this occurs, the NK Technologies’ relay will open a contact to de-energize the operating coil of the contactor supplying the cable power. (Fig. 1)

The National Electric Code (US) and Canadian Electrical Code require that most heating loads be disconnected from the supply when ground or earth faults occur that may damage equipment. This will keep the risk of fire from arcing to a minimum. The amount of current that will flow to ground before the relay disconnects the load from the supply is not well defined in any place in the NEC. Relying on the circuit overcurrent will protect the wire feeding the load but not the equipment if the leakage current to earth is lower than the circuit protection level. A two-inch block of carbon steel will begin to glow when it is conducting about 500 mA. To avoid damage the ground fault protection should be lower than this.

Section 427.22 of the NEC states that each branch circuit supplying electric heat equipment shall have “ground-fault protection of equipment” with exceptions. The main exception is that in industrial environments, continued operation of the heating equipment is necessary for safe operation of equipment or processes. In these cases, the circuit need not be disconnected from the supply, but an alarm shall be required.

This photo is of a church in Vail, Colorado. They use Easy Heat snow melting mats embedded in the sidewalks.(Courtesy of Easy Heat.)

The manufacturers of circuit breakers have standardized a trip point of 30 mA for GFCI equipment protection. This works in most installations but there are many applications where this may be too low to alleviate nuisance or spurious tripping. With NK Technologies’ ground fault relays, the non-adjustable Tri-Set models have a field selectable trip point of 5, 10 or 30 mA, but it is much more common for customers to order NK Technologies’ relays with a single trip point set to trip at 30 mA. If they have problems keeping the heat trace online or there are too many alarms, the trip point can be adjusted to a higher level, up to 100 mA. Another single set point model has a minimum trip point of 80 mA, and can be adjusted up to 950 mA.

Some installations are designed so the relay contact operates in a “fail safe” mode. Here, the relay operates the output contact as soon as the power supply energizes the relay. These models have a reverse contact action when the fault current exceeds the trip point, or if the power supply is lost.

Detailed examination of the control circuit is recommended. Imagine this scenario: An auto-reset ground fault relay trips due to a fault over the trip point thereby de-energizing the offending load. This removes the fault current, and will cause the ground fault relay to return to the untripped condition. If this contact action again re-energizes the load and the fault is still present, the relay will trip again, setting up a cycle of frustration for the user.

NK Technologies is constantly working on improvements to their relays. If you would like to speak with an expert in the field of current relaying regarding your specific application, please contact our technical support representatives.