The flexible cable current sensing method, often referred to as Rogowski coils, was refined in 1912 by engineers Walter Rogowski and W. Steinhaus. This method of measuring AC current has some very attractive features. There is no iron core, making the device much lighter and easier to install than toroid-based current transformers. Since there is no permeable core the coils cannot be saturated with high current conditions making them just as accurate with higher circuit frequencies (up to 1MHz) as when monitoring 60 Hz. The flexibility allows the cable to surround multiple conductors or bus assemblies regardless of the shape.

CTRC Current Transformer for Power Monitoring

NK Technologies’ CTRC current transformers use the Rogowski coil as the first step in power monitoring. Each coil is matched with a signal integrator, and the output is calibrated for the highest degree of accuracy possible. The resulting 1/3 volt at full range current mirrors the primary circuit wave shape with less than 0.5 degree difference in the phase angle and overall linearity of better than 1% of the full scale output. When matched with the circuit voltage wave shapes, a highly accurate representation of the system power, measured in watts, can be derived.

The signal integrator is housed in a compact, DIN-compatible enclosure, with 1.5 meter (59 inches) of lead cable from the sensing loop to the integrator. The signal integrator is powered with 24 volts, AC or DC, consuming less than one watt each. The narrow dimension of the lead cable (0.87 inches) allows for installation in very close quarters, easily passing between the monitored conductor and the adjacent phase. The coils are rated to 600VAC and do not require shorting blocks between the integrator and the connected load. Even when the current through the loop exceeds the design range the low voltage output remains at non-hazardous levels.

Related Products

Power Monitoring Applications

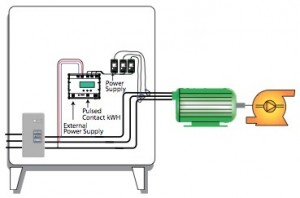

- Motors

Measure motor power consumption when current alone provides insufficient resolution - Machine Tools

Monitor finishing operations such as deburring - Car Wash Systems

Sense brush entanglements - Pumping Systems

Detect dry run, blocked intake or discharge lines, bearing failures and cavitation - Cost Allocation

Monitor the power usage of each machine, process, building or the entire facility