Understanding GFCI, GFPE, and Class A Solutions

Electrical safety is paramount in residential, commercial, and industrial settings. Class A Ground Fault Circuit Interrupters (GFCIs) and Ground Fault Protection for Equipment (GFPE) solutions are critical components designed to enhance safety by mitigating risks associated with ground faults. While these devices share a common goal of preventing electrical hazards, they differ significantly in their applications, sensitivity levels, and compliance with the National Electrical Code (NEC).

Ground Fault Circuit Interrupters (GFCIs)

GFCIs are designed to protect individuals from electrical shock by detecting ground faults and interrupting the circuit. According to the NEC, GFCIs are required for specific appliances and locations where water and electricity are likely to come into contact, such as bathrooms, kitchens, and outdoor receptacles (NEC Article 210.8). These devices monitor the current flowing through the hot and neutral wires and trip the circuit if an imbalance is detected.

Class A

The NEC (2020/2023) explicitly defines Class A GFCIs in article 100, which narrows the GFCI behavior to values established by a Class A device. Class A devices trip when ground fault currents exceed 6 mA but do not trip below 4 mA. These devices are specifically designed for personnel protection and function to de-energize a circuit within an established period of time.

This sensitivity ensures that even minor ground faults are promptly addressed, reducing the risk of severe injuries or fatalities. Class A GFCIs are widely used in residential and commercial applications. They’re the standard for most GFCI applications, ensuring compliance with safety regulations and providing reliable protection against ground faults.

Ground Fault Protection for Equipment (GFPE)

GFPE devices are designed to protect electrical equipment rather than personnel and are commonly used in industrial and commercial settings. They operate at higher trip thresholds, typically 30 mA or greater, depending on the application. The NEC mandates the use of GFPE in specific scenarios, such as protecting feeders and branch circuits in large installations (NEC Article 215.10). Unlike GFCIs, GFPE devices are not intended to prevent electrical shock but to safeguard equipment and maintain operational continuity.

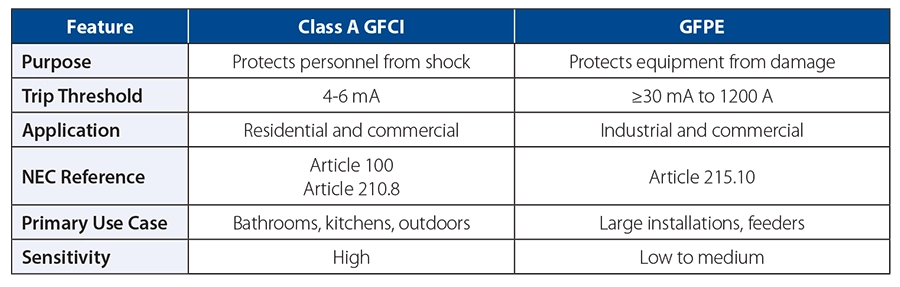

Key Differences Between Class A GFCI and GFPE

GFCI vs GFPE Conclusion

In summary, Class A GFCIs and GFPE solutions play distinct roles in enhancing electrical safety. Class A GFCIs prioritize personnel protection and are the standard for most applications. GFPE devices, on the other hand, focus on safeguarding equipment in industrial and commercial environments. Understanding these differences is crucial for ensuring compliance with the NEC and selecting the appropriate device for each application.

By adhering to NEC guidelines and leveraging these devices’ unique capabilities, we can create safer electrical systems that protect individuals and equipment from the dangers of ground faults.

Resources & Downloads

Contact Us for Assistance

"*" indicates required fields

Here is what Engineers have to say about our technical expertise...

“Changes to NEC 210.8 B-F have challenged all of us in the industry to find new GFCI solutions. When NK Technologies reached out to us recently, we decided to invest a few hours into meeting with their application experts. Five of our electrical engineering designers attended the session and considered it time well spent. NK Technologies has an in-depth understanding of the new NEC requirements and ground fault products designed to meet them. We are thankful for their time.”

PK Electrical

One of the top electrical and low voltage/communications design firms,

in both the private and public sectors, based in Reno, NV and Denver, CO.