In the early 2000’s, NK Technologies’ engineers designed a larger relay with the capacity to monitor circuits up to around 300 amps. For applications drawing more current or using conductors that are larger than would fit through the relay window, an external “zero sequence” current transformer was needed; the fault would be expressed at 10% of the actual fault current. To increase the amount of current through the relay, the CT secondary is looped two or three times through the relaying aperture to get the current up to a detectable level. This approach is not very attractive, even to those who frequently install electrical equipment in less than ideal conditions. Now the design engineers at NK have developed a relay with an aperture measuring four inches in diameter. This allows conductors carrying 800 amps or more to pass through easily.

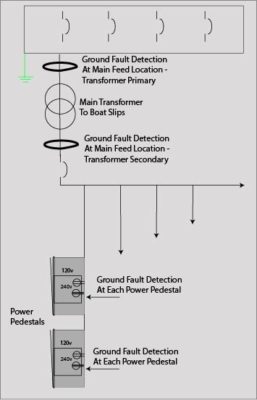

The National Electric Code 2011 added section 555.3 to require ground fault circuit protection for all circuits feeding a dock. The trip point was specified to be 100 mA. The 2017 Edition reduced that trip point to 30 mA. Not all jurisdictions have accepted this lower detection level, but they may in the future. The smaller NK Technologies’ relays can be used to monitor individual circuits to each slip at a dock, with the relay output energizing a shunt trip breaker operating mechanism circuit. The entire feed can be used to monitor the main feeding circuit to the pedestals, to again complete the circuit to operate a shunt trip breaker.

Docks and marinas are not the only place where higher current circuits should be protected with ground fault protection relays. Adding ground fault protection to amusement park rides, whether permanently installed or temporary, should be considered even in places where it is not specifically required under NEC section 525 or 518. The last thing anyone would want is to be shocked while taking the newest roller coaster at their favorite theme park.

AG-LC Ground Fault Sensors for Monitoring Higher Current Circuits

AG-LC series ground fault relays are the latest design innovation from NK Technologies. The NEC added section 555.3 to require ground fault protection of the main over current device feeding marinas and boat yards. These services are often carrying up to 800 amps; most sensor designs will not allow the conductors to pass through a single sensing ring. By designing a relay in a large solid-core housing, the conductors will not have to be passed through a separate relay device like a zero sequence current transformer. This design makes monitoring of larger circuits a breeze, whether to protect boaters, or large equipment like amusement park rides or gantry cranes.