Challenge: Fabricating silicon wafers into semiconductor chips involves many hazardous chemicals and extreme heat that must be precisely controlled. The SEMI standard S22-071b provides guidelines regarding the safety of semiconductor processing equipment, including Emergency Mains Off (EMO) circuitry design. This requires that if any problem occurs during processing, the operator can easily disconnect main power. With electrical heating elements used throughout the fabrication equipment, ground fault protection is paramount. As the elements are monitored in each process segment, ground fault relays are set at a fairly low trip point. As a fault to earth through the heating element occurs, relays will selectively shut down only that part of the process. During a situation where several heating processes short at once, a relay with a bit of delay and higher trip point will shut off the main power feed.

Challenge: Fabricating silicon wafers into semiconductor chips involves many hazardous chemicals and extreme heat that must be precisely controlled. The SEMI standard S22-071b provides guidelines regarding the safety of semiconductor processing equipment, including Emergency Mains Off (EMO) circuitry design. This requires that if any problem occurs during processing, the operator can easily disconnect main power. With electrical heating elements used throughout the fabrication equipment, ground fault protection is paramount. As the elements are monitored in each process segment, ground fault relays are set at a fairly low trip point. As a fault to earth through the heating element occurs, relays will selectively shut down only that part of the process. During a situation where several heating processes short at once, a relay with a bit of delay and higher trip point will shut off the main power feed.

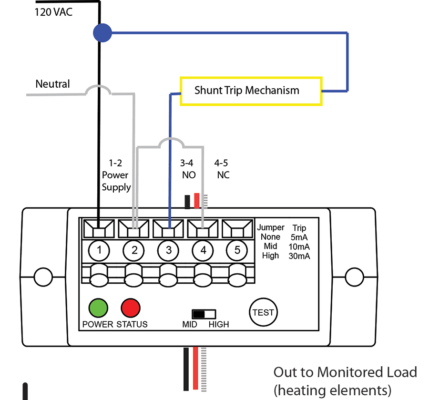

Solution: NK Technologies wide range of ground fault relays are ideal for the semiconductor manufacturer, allowing optimization of each portion of the fabrication process while protecting machine operators and minimizing or eliminating potential damage to expensive materials. AG ground fault relays and AGL ground fault relays with adjustable setpoint and delay will help manage the controlled shut down of the system in case of critical failures.