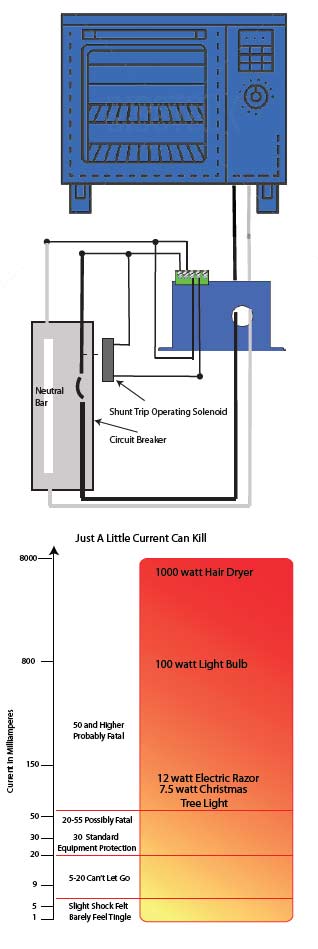

If the circuit breaker feeding the equipment can be fitted with a shunt trip operating mechanism, the AG or AGL series sensors with auto reset contacts will detect the fault, and, in turn, will close the circuit to energize the shunt trip solenoid. If the equipment is operated with a magnetic contactor, the sensor used should be the latching output type. The NK Technologies’ sensor contact will be connected to de-energize the contactor coil when a fault is detected.

A major manufacturer of commercial kitchen steamers and grills has reported that their equipment may retain humidity during storage and should be “burned in” or energized for a minimum of two hours with the sensor set at 30 mA. Then, after the equipment has dried out, the sensor trip point can be reset to 5 mA.

NK Technologies offers a tri-set sensor which has this capability. A range jumper is placed at the factory in the highest trip point, 30 mA. By removing this jumper after the equipment has dried, the trip point will be set at 5 mA.

Resetting the trip point to 5mA will cause the circuit with a fault to earth to be disconnected in a very brief period of time, faster than the GFCI outlet in a bathroom works when a fault is detected below 100 mA. A human heart will stop beating when hit with 100 mA or more.

The most important thing to remember is that when a fault to earth occurs, de-energizing the circuit as quickly as possible will keep people working near the equipment as safe from electrocution as possible.

For more information on ground fault sensing, get NK Technologies’ Ground Fault Sensing White Paper.

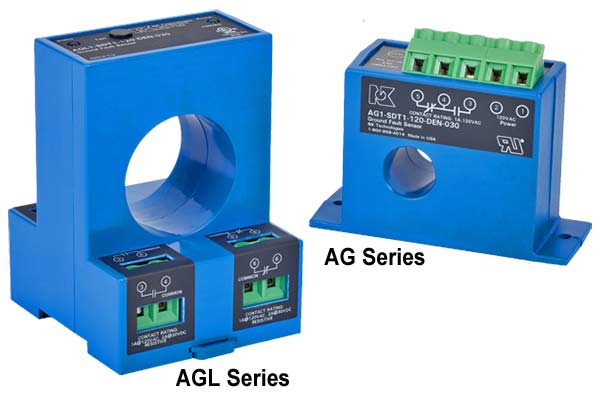

AG and AGL Ground Fault Sensors