Press Releases

The Industrial and Commercial Canary in a Coal Mine

Motors are used everywhere in industrial and commercial automation applications. Various means are available to determine whether a motor is running, such as an indicator light connected to the motor power input. However, knowing that a motor is operating optimally and within specifications requires a different approach.

Motors have shaft bearings, and those bearings will wear over time. The source of a motor failure, such as bearing wear, can be used to provide an early warning of impending failure. A power transducer or current transducer can help prevent equipment damage and unplanned downtime by providing advanced warning that a motor might fail or is overloaded.

Early Warning Methods

Years ago, in the hard coal mining industry in Pennsylvania, long before gas detection devices were available, miners would carry a canary deep into the coal mines with them. They would keep an eye on the canary to determine whether harmful gases such as carbon monoxide were present in the mine. If the canary collapsed, it was the miners’ early warning to evacuate the mine shaft until the source of the toxic gas could be located and eliminated before they, too, fell victim.

A power or current transducer can be used in much the same manner as the canary once was. Transducers can be used to create an early warning that then can be used to investigate a potential problem’s source well before a catastrophic event occurs. Think of it as an “electronic problem detecting canary in a coal mine.”

As motor bearings wear, the motor will work harder to overcome the increased resistance associated with shaft bearing wear. The effect of increased resistance is reflected in the current a motor is drawing.

As the bearings wear, the motor current draw will increase proportionally. A power or current transducer installed on one conductor of an AC motor can be used to monitor the motor’s current draw. The current transducer’s analog output can be connected to a programmable logic controller’s (PLC’s) analog input card. The PLC can, in turn, be programmed to issue an alert or sound an alarm when the motor current exceeds the motor current draw associated with an optimally functioning process.

NK Technologies Releases New Ground Fault Detection Tech Guide

San Jose, CA – November 7, 2019 – NK Technologies (www.nktechnologies.com) has released a new educational resource for engineers. The Ground Fault Considerations Tech Guide covers a wide range of topics and includes an easy-to-use selection guide, as well as a variety of case studies and application examples.

Highlights include:

- Ground fault detection basics

- Ground fault sensing basics

- Consolidated ground fault sensors selection guide

- Case studies

- Application examples

- Design considerations for earth fault protection

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well-positioned to respond with sophisticated new product designs and improved product functionality necessary to meet

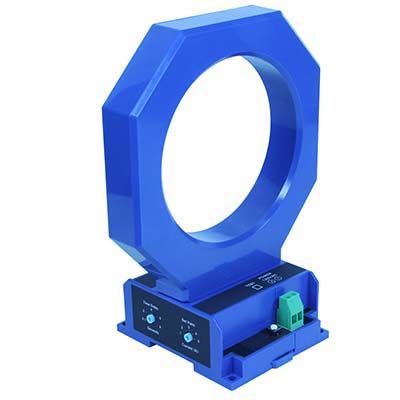

AG-LC Series Ground Fault Sensor: New Large Solid-Core Design Ideal for Monitoring Larger Circuits

Key applications include:

- Monitoring large machines: Detecting leakage to earth before the problem can cause damage

- Water treatment and delivery: Keeping pumping systems safe and in operation

- Generators: Shut down equipment when leakage current exceeds hazardous levels

AG-LC Series highlights include:

- Electromechanical relay output provides both normally open and normally closed contacts

- Compatible with most automation and control systems

- Externally powered – choice of fail-safe or standard operation

- Simple field setpoint adjustment

- Adjustable time delay

- DIN Rail or panel mount

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well-positioned to respond with sophisticated new product designs and improved product functionality necessary to meet

NK Technologies Releases 2019 Product Catalog:

Featuring New Current, Voltage & Power Solutions for Industrial/Factory Automation Markets

SAN JOSE, CA – December 17, 2018 – NK Technologies has released the 2019 product catalog, which features performance data, sizes, specifications, and technical references for the company’s extensive portfolio of current sensing switches, transducers, transformers, and ground fault protection products. Interested parties may download the interactive PDF catalog here, or request a printed copy of at info@nktechnologies.com.

Featured in the new catalog are recently-introduced products including:

AT/ATR-TH and DT-FD Current Transducers:

The AT/ATR-TH monitors three-phase loads, motors, machines, or buildings with a large triple-aperture solid-core design that allows for quick and easy installation. Transducer outputs are powered from an excitation voltage of 24 VAC or DC, or optionally 120 VAC, isolated from the monitored circuit. The DT-FD is a high voltage DC current transducer with a large sensing window and the ability to monitor circuits with voltages up to 1500 VDC.

ASP-FD and DS1-FD Current Sensors:

The ASP-FD allows two separate trip points to detect overcurrent and undercurrent conditions. The sensor outputs are dual, single-pole, double-throw relays, that can control either AC or DC circuits. The DS-FD monitors AC or DC loads: motor, crane, or welding equipment. The relay features a large aperture and solid-core design for quick installation. The relay output is isolated from the monitored circuit and can switch up to two amps up to 125 VAC, or two amps to 30 VDC.

AGT-FD and DG Ground Fault Sensors:

The AGT-FD detect faults to earth from 0 mA to 100 mA and produces an output signal of 0–10 VDC in proportion to the amount of current passing to ground. The output is equal to the RMS value of the earth leakage. The AGT-FD can also be used to measure and monitor any low value AC circuit current. The DG's one-piece, solid-core design allows for installation over wires

feeding loads to about fifty amps. The output relay will change state at factory setpoint between 5 and 50 mA of DC current to earth.

“The 2019 catalog showcases our newest products as well as enhancements and increased functionality of existing products,” said Philip Gregory, President of NK Technologies. “With more than 1300 cost-effective, high-performing models available, we offer one of the broadest and most innovative selections in the industry.”

You can find the company’s full line of products, engineering resources, distributor/partner lists, and more at https://www.nktechnologies.com.

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well-positioned to respond with sophisticated new product designs and improved product functionality necessary to meet

AGT-FD Ground Fault Sensor: Large Sensing Window Makes Monitoring 100 A Circuits Easy

The AGT-FD Series is ideal for monitoring earth leakage current for applications including: electric heating processes, AC motor loads, semiconductor wafer fabrication, plastic molding processes, heat trace cable systems, and snow melt protection.

Features include:

- Analog output signal, 0–5 or 0–10 VDC proportional to 0–100 mA

- Externally powered, 24 VAC or DC(20-30V)

- Factory calibrated, warrented to stay accurate for minimum of 5 years

- Panel mount or simple snap onto DIN rail

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well-positioned to respond with sophisticated new product designs and improved product functionality necessary to meet

New DT-FD Series DC Current Transducer from NK Technologies Monitors Circuits with Voltages Up to 1500 VDC

Features include:

- Industry standard analog output

- Externally powered 24 VAC or DC

- Factory-set calibration reduces setup time

- Large sensing window with ample space for single or multiple conductors

- Designed for UL, CUL and CE approval for use worldwide

The DT-FD is ideal for applications such as monitoring large solar panel installations, motors in traction and drilling equipment, uninterruptible power supplies (UPS), and telecommunication towers, among many others.

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well-positioned to respond with sophisticated new product designs and improved product functionality necessary to meet

New 2018 Product Catalog Available from NK Technologies

Current, voltage and power solution products for industrial & factory automation markets

Current, voltage and power solution products for industrial & factory automation markets

SAN JOSE, CA – January 2018 – NK Technologies announces the publication of its 2018 catalog, which includes performance data, sizes, specifications and technical references for the company’s extensive line of current sensing switches, transducers, transformers, ground fault protection and other products.

Innovative new products featured in the catalog include the ASP-FD Current Operated Switch, which allows two separate trip points detect overcurrent and undercurrent. Sensor outputs are dual, single-pole, double-throw relays that can control either AC or DC circuits. The new APT-TH Power Transducer is a one-piece solution for measuring power – no external current transformers needed. It monitors watt consumption of three-phase loads and provides an analog signal proportional to the active power consumed by the monitored load. The three current-carrying conductors pass through the three windows of the top section and the matching voltage input at the terminals.

“The 2018 catalog showcases our newest products, as well as enhancements and increased functionality of existing products,” said Philip Gregory, President of NK Technologies. “With more than 1,300 cost-effective, high-performing models available, we offer one of the broadest selections in the industry.”

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well-positioned to respond with sophisticated new product designs and improved product functionality necessary to meet

New DG Series DC Ground Fault Relay Protects Machinery and Operators from Accidental Shocks

Features include:

- Electromechanical relay outputs

- Externally powered with choice of fail safe or standard auto reset, or latching contact

- Solid core case - ample sensing window for multiple conductors

- Designed for UL, CUL and CE approval for use worldwide

Applications include:

- Monitoring Photovoltaic Panels: Detect fault currents before damage can occur

- Water Treatment and Delivery: Detect moisture ingress in submersible pumps

- Heating Processes: De-energize circuits quickly if an element shorts to ground

- Communications Towers: Monitor and notify if a battery-powered supply is allowing current to earth

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well-positioned to respond with sophisticated new product designs and improved product functionality necessary to meet

NK Technologies Introduces New VTU-DIN Series: True RMS AC or DC Voltage Transducer in Space-saving Design

The VTU-DIN Series features zero to 5-KHz measurement for situations where the power supplied is non-sinusoidal (such as VFD applications), poor quality installations or other electrically harsh or challenging environments. It effectively detects a wide range of conditions that may cause damage to the motor and/or soft starter components (SCRs), including: below normal/brown-out, phase loss and over voltage conditions.

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well-positioned to respond with sophisticated new product designs and improved product functionality necessary to meet those applications.

NK Technologies, 3511 Charter Park Drive, San Jose, CA 95136; 800.959.4014; fax: 408.871.7515 sales@nktechnologies.com; www.nktechnologies.com.

New 2017 Product Catalog Available From NK Technologies

Current, voltage and power solution guide for industrial & factory automation markets

SAN JOSE, CA – November 14, 2016 – NK Technologies announces the publication of a new catalog featuring its extensive portfolio of current, voltage and power measurement products. The 2017 catalog includes performance data, sizes, specifications and technical references for the company’s line of current sensing switches, transducers, transformers, ground fault protection and other products.

Featured in the new catalog is the recently introduced AT/ATR-FD Series current transducer with a larger aperture (1.31” inside diameter) to accommodate wire sizes for loads up to 400 Amps. Other additions include the VTU voltage transducer, which can measure AC or DC circuit voltages up to 1200 Volts with a single sensor, and the VTU-DIN Series, a voltage transducer in a slim, space-saving design able to measure AC (True RMS) or DC to 600 volts.

“The 2017 catalog showcases our newest products as well as enhancements and increased functionality of existing products,” said Philip Gregory, President of NK Technologies. “With more than 1300 cost-effective, high-performing models available, we offer one of the broadest selections in the industry.”

You can find NK Technologies’ full line of products at www.nktechnolgoies.com or download a PDF of the new catalog here.

ABOUT NK TECHNOLOGIES

Founded in 1982, NK Technologies designed the first low-cost solid-state current sensing technology that underlies the industry today.

Today, NK Technologies is a leading provider of current sensing, ground fault detection and power monitoring products to the industrial and factory automation markets, with a product portfolio that includes more than 1300 models to satisfy a wide range of specific application needs. As the needs of these markets change, NK Technologies is well positioned to respond with sophisticated new product designs and improved product functionality necessary to meet those applications.

NK Technologies, 3511 Charter Park Drive, San Jose, CA 95136; 800.959.4014; fax: 408.871.7515 sales@nktechnologies.com; www.nktechnologies.com.

Current, voltage and power solution products for industrial & factory automation markets

Current, voltage and power solution products for industrial & factory automation markets