Power transducers monitor both the current and the voltage of a load simultaneously, and also takes power factor into account by comparing the phase angles of each. Purely resistive loads can be accurately measured in all conditions by monitoring current only, but inductive loads, such as squirrel cage motors, will display current flow which does not change as linearly as a strictly resistive load.

Power transducers monitor both the current and the voltage of a load simultaneously, and also takes power factor into account by comparing the phase angles of each. Purely resistive loads can be accurately measured in all conditions by monitoring current only, but inductive loads, such as squirrel cage motors, will display current flow which does not change as linearly as a strictly resistive load.

Motors that are oversized for their intended use operate at low power factor; the current used changes little from no load (open shaft condition) to maximum if the motor has a much larger capacity than is needed to move the connected load. A motor rated for 20 horsepower connected to a load which needs 10 horsepower to move will not draw full load current unless there is a jam resulting in locked rotor current. This is close to the amount of current used during starting, but unlike inrush current which last for a brief period, locked rotor current lasts until over current protection operates to shut the circuit down.

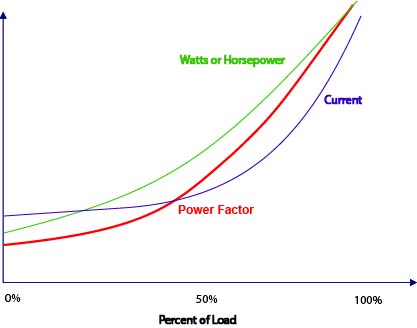

Power is calculated by measuring the current in amperes multiplied by the voltage and then multiplied by power factor in single phase circuits. Three phase power is calculated in the same manner, but the result is multiplied by the square root of three or 1.732. The result in either case is the watts being used. The power factor improves as a motor load is increased to its design capacity. As this occurs, the current reaches the motor’s Full Load Ampere rating (FLA).

By comparing the current waveform with the voltage waveform, a true representation of the actual wattage (horsepower) being consumed can be provided by a power transducer in the form of a 4–20 mA, 0 - 5 or 0–10 VDC signal proportional to the watts used. The transducer output is read by a panel meter, PLC or data logger. Power transducers tend to be more expensive when compared to sensors that measure current only, especially when three phase loads are to be monitored as amps are measured in three places, and the voltage matched with the current.

Comparing what the utility is charging for the power supplied and the cost of replacing or repairing a drive motor is more easily calculated by measuring watts rather than just measuring current, since the utility bills for watts. This cost comparison helps to determine how extensive the predictive maintenance should be, and what investment in sensors, data acquisition and analysis is economically feasible to support the ability to detect a problem before it causes destruction or damage. For example, with a regular maintenance program, pump impellers that force material through a process will be cleared and cavitations repaired on a timely basis, bearings will be lubricated, and filters or screens will be replaced or cleaned. These common maintenance issues that cause a drive system to draw more current than normal are eliminated. An increase in required torque to move the pumped product will be reflected as an increase in current draw of the drive motors, subsequently an increase in wattage. This signal will be sent to the process controller. Limit alarms can be set to sound, alerting the operator to adjust the process temperature higher or lower, or adjust the process in some other fashion.

Power Monitoring Transducers

Power Monitoring Transducers

NK Technologies offers a variety of power monitoring options. The APS covers applications of single phase or three phase circuits of about fifty amps, with current balanced across all three phases. The APT-TH measures power in three phase circuits from 208 to 600 volts, maximum of about 200 amps, with no external current transformers needed. The APT-DIN and the APN series connect to either 5 amp secondary current transformers or ProteCT™ low voltage output sensors. The APT-DIN measures three phase loads with voltages from 120 to 600 volts AC. The APN produces a digital Modbus RTU formatted data package showing voltage, current, power factor, KVA and wattage. There is also a pulsed contact which opens and closes as KWH are accumulated. The current can go to 3000 amps. The APN-R series with its Rogowski coils, and can measure circuits to 2000 amps and 600 volts.

Power Monitoring Transducers

Power Monitoring Transducers